Choosing the wrong ERP vendor

Manufacturing is a highly specialized industry, each field has its own operating processes and problems. Therefore, although there are many ERP software providers in the market, both domestic and foreign, not all providers can design specialized solutions suitable for the requirements of manufacturing enterprises.

Choosing the wrong supplier not only costs businesses a lot of time and money, but the system after implementation also does not meet expectations.

Advice for businesses:

To choose the right supplier, before implementing ERP, businesses need to clearly define the scope of the project, specific requirements and list suppliers capable of solving the business's problems. In addition, businesses can refer to customers who have successfully implemented ERP of that supplier to have a more objective and accurate assessment.

ITG has experience in successfully implementing ERP for many manufacturing enterprises.

One of the prestigious ERP implementation units in the market today is ITG Technology . The company has nearly 20 years of experience in researching and implementing ERP for manufacturing enterprises in various fields such as: Mechanics - Manufacturing, Electronics, Plastic molding, Packaging, Pharmaceuticals, Construction materials, Electric wires and cables... and is the choice of many FDI enterprises from Japan, Korea as well as enterprises in VNR500. The special feature of this solution is that it is drawn from Knowledge and Experience (Know-how) according to each industry, with the ability to flexibly customize according to the production characteristics of the enterprise, so it can well meet the specialized requirements of manufacturing enterprises.

Choosing ERP software with functions that are not suitable for manufacturing enterprises

ERP is a system that helps businesses manage and optimize core business processes (Purchasing, Sales, Warehouse, Accounting, Production, Human Resources, Distribution Channels...) on one platform.

However, not all ERP software provides functions that meet the specific production and business requirements of enterprises. Deploying an ERP software with too many functions but not really necessary can complicate the system, increasing the cost of implementation and operation. On the contrary, if choosing a lack of functions, enterprises may have difficulty in production management.

Advice for businesses:

To optimize production management efficiency, businesses need to carefully analyze the current production process, identify the necessary functions to support production management activities (raw material management, factory capacity management, production planning, etc.). In addition, businesses also need to compare ERP software from different suppliers, evaluate the functions, customization and integration capabilities to make the optimal choice.

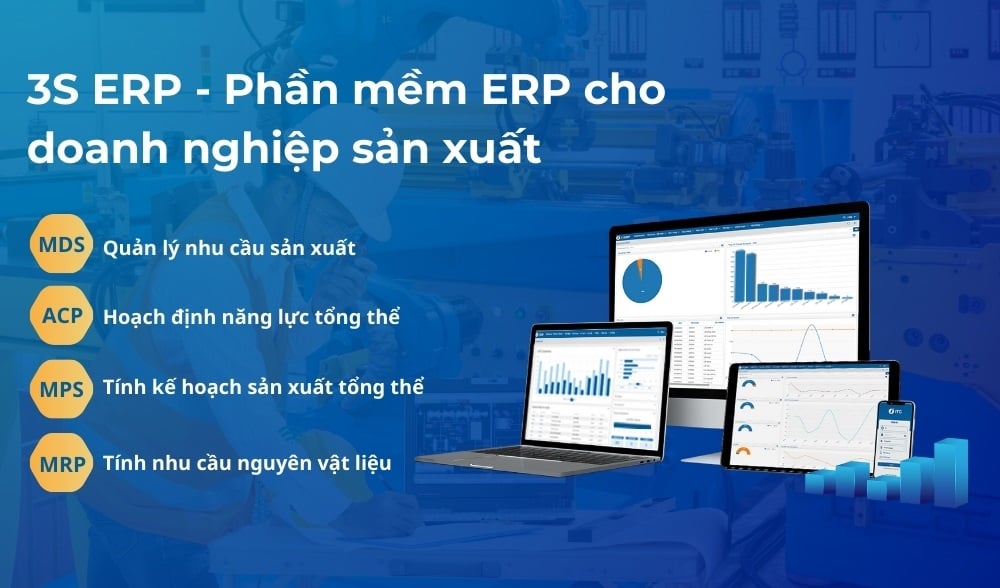

3S ERP has specific features suitable for manufacturing enterprises.

For example, ITG's 3S ERP solution is one of the few ERP software on the market today that has a Production Management function. In addition to the basic subsystems that support office management, this subsystem of 3S ERP provides specialized features such as: Planning, material norm management, factory capacity management... helping managers understand the operating process at the factory, and at the same time plan the allocation of resources (Machines, Materials, People...) quickly and appropriately.

No clear ERP implementation strategy

One of the common mistakes of manufacturing enterprises when implementing ERP is not having a clear strategic direction. Without a detailed plan on scope, goals, and implementation roadmap, enterprises will have difficulty in managing projects, controlling costs and ensuring progress, and at the same time, cannot take full advantage of the benefits that this software brings, leading to a waste of resources and not achieving the desired results.

Advice for businesses:

To avoid failure when implementing ERP, businesses need to develop a specific strategy, clearly stating the goals, scope, project implementation roadmap and KPI indicators to be achieved. Businesses can also seek out reputable ERP software providers with in-depth knowledge of the industry and manufacturing sector to get advice on a suitable and systematic ERP implementation roadmap.

A well-planned implementation strategy will help businesses ensure the progress and effectiveness of ERP projects.

In addition, during the software development process, project team members need to regularly check and evaluate the plan to promptly adjust when there are changes, ensuring that the ERP system brings optimal efficiency to production activities.

It can be seen that choosing the wrong supplier, choosing the wrong function or not having a clear implementation strategy can all be the reasons for the failure of ERP implementation of manufacturing enterprises. If your enterprise is planning to implement ERP, avoid the above mistakes to maximize efficiency and bring real value to the enterprise./.

AT

Source: https://baolongan.vn/3-sai-lam-dien-hinh-cua-doanh-nghiep-san-xuat-khi-trien-khai-erp-a194356.html

![[Photo] Hanoi is brightly decorated to celebrate the 50th anniversary of National Reunification Day](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/4/29/ad75eff9e4e14ac2af4e6636843a6b53)

![[Photo] Nghe An: Bustling atmosphere celebrating the 50th anniversary of Southern Liberation and National Reunification Day](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/4/29/64f2981da7bb4b0eb1940aa64034e6a7)

![[Photo] Prime Minister Pham Minh Chinh meets to prepare for negotiations with the United States](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/4/29/76e3106b9a114f37a2905bc41df55f48)

![[Photo] Ho Chi Minh City: People are willing to stay up all night to watch the parade](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/4/29/cf71fdfd4d814022ac35377a7f34dfd1)

![[Photo] General Secretary attends special art program "Spring of Unification"](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/4/29/e90c8902ae5c4958b79e26b20700a980)

![[Photo] People choose places to watch the parade from noon on April 29](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/4/29/3f7525d7a7154d839ff9154db2ecbb1b)

Comment (0)