Automatic pumping tunnel system applied at Nui Beo Coal Joint Stock Company.

10 years ago, the coal industry was associated with a heavily manual production model, semi-mechanized mining, and heavily dependent on human labor. Low labor efficiency, high safety risks, and harsh working environments were barriers to TKV’s sustainable development. In that context, TKV chose a turning point direction, comprehensive modernization with the “3-ization” strategy.

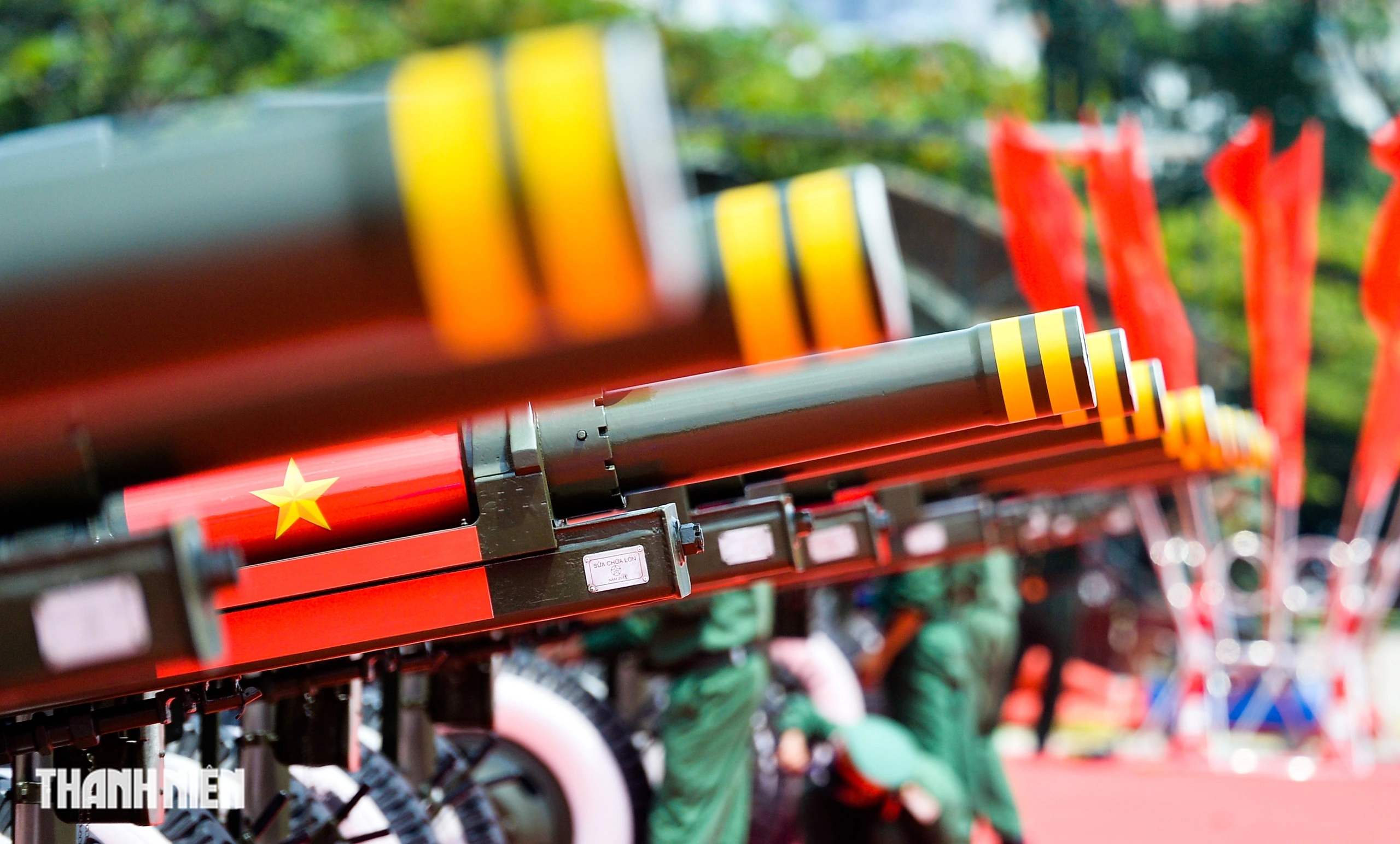

The strategy is not simply about investing in equipment, but also about a fundamental shift in production thinking and management methods. TKV has gradually transformed open-pit and underground mines into increasingly modern construction sites and production workshops. Modern technologies such as roadheader excavators, mobile hydraulic supports, automatic conveyors and remote-controlled drilling and blasting systems have been synchronously deployed..., not only helping to increase productivity, but also contributing to significantly reducing the number of direct workers in dangerous environments, enhancing labor safety, and at the same time opening up opportunities to restructure the workforce towards leanness and high quality.

The success of the "3-industry" strategy has created a new look for the coal industry - more modern, safer and more sustainable. According to TKV's data, by 2024, the mechanization rate in underground mining will reach over 70%. Many large mines such as Ha Lam, Khe Cham, Mao Khe... have applied self-propelled supports, excavators, conveyor transport systems and self-propelled cars. Thanks to the application of mechanization, mining productivity has been significantly improved, increasing by an average of 20-30% compared to traditional methods; the number of workers directly going down to the mine has decreased sharply, contributing to ensuring labor safety and significantly improving working conditions.

Not only stopping at equipment, the Coal industry is going further with remote control automation systems, closely monitoring all coal mining processes. Some units such as Ha Lam Coal, Ha Long Coal, Nam Mau Coal, Mao Khe Coal... have invested in centralized operating systems, helping to control the entire production process. TKV promotes computerization in business management and operation; applying ERP software, Big Data systems, artificial intelligence (AI) to help improve forecasting efficiency and optimize operations.

The warehouse and port system at Cua Ong Coal Selection Company is invested synchronously and modernly to serve production.

Thanks to the application of these technologies, the coal industry has improved working conditions, ensured safety and increased labor productivity. In 2014, the average productivity of underground miners was only about 400-450 tons/year. By 2024, it will increase to over 650 tons/year, with some units reaching 700-800 tons.

In the international context of reducing emissions, TKV invests in green technology, such as: Mine wastewater treatment system, planting trees to cover waste dumps, using renewable energy in production areas. In the development strategy for the period 2025-2030, TKV not only aims to increase output, but also transform from a traditional mining model to a modern, smart and green industry.

The focus of this strategy is to increase the automation rate in the entire industry to 80%, gradually reducing direct labor in underground mines in stages such as digging, loading coal, and transporting materials, thereby minimizing the risk of occupational accidents and improving the accuracy of production operations. At the same time, building a high-tech engineering force as the core for sustainable development. This is the core force capable of operating, monitoring and optimizing automatic machinery systems, remotely controlled through real-time data and artificial intelligence.

Mr. Nguyen Huy Nam, Deputy General Director of TKV Group, said: TKV continues to deploy a series of synchronous solutions, especially in training and skill transfer for the workforce. One of the key strategies is to invest heavily in specialized training programs, focusing on improving the capacity of workers and engineers, helping them keep up with new technology trends and meet the increasing demands of the industry.

TKV has cooperated with domestic and international training institutions to develop specialized courses on automation, mechanization and computerization. These courses not only help workers gain basic knowledge of new technology but also train them in operating modern equipment such as automatic tunneling machines, truss systems, drilling machines and remote control systems.

Pham Tang

Source: https://baoquangninh.vn/nhung-buoc-tien-cua-nganh-than-3355441.html

![[Photo] An Phu intersection project connecting Ho Chi Minh City-Long Thanh-Dau Giay expressway behind schedule](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/8/21/1ad80e9dd8944150bb72e6c49ecc7e08)

![[Photo] Politburo works with the Standing Committee of Hanoi Party Committee and Ho Chi Minh City Party Committee](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/8/21/4f3460337a6045e7847d50d38704355d)

Comment (0)