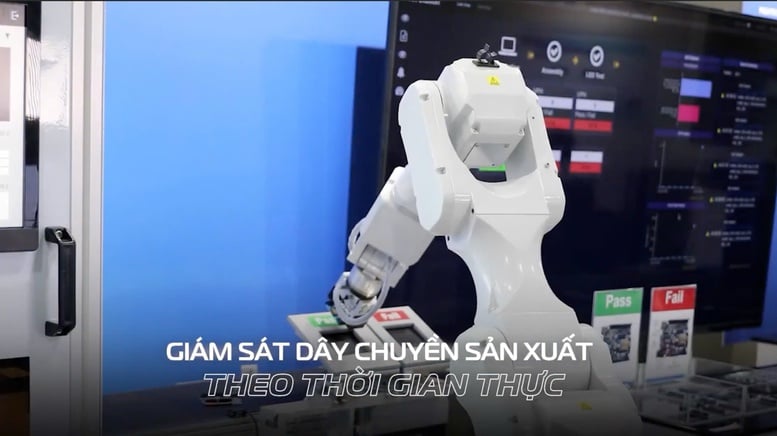

Machines operate automatically, robots appear at every stage to reduce human labor, production activities are monitored throughout the process... and all are connected on the 5G network infrastructure, which is the vision of smart manufacturing that Viettel 's 5G2B has been and is realizing.

On the 5G connection platform, the production process will be optimized to increase speed, accuracy and flexibility to the maximum level.

Irreversible trend In a report published in April 2024 on Market.us, the global smart factory market size is expected to increase from 292.7 billion USD in 2023 to 1,021.5 billion USD in 2032, with a compound annual growth rate (CAGR) of 14.9%. Combining advanced technologies such as the Industrial Internet of Things (IoT), artificial intelligence (AI), robotic automation, big data and edge computing... on the 5G connection platform, the production process will be optimized to increase speed, accuracy and flexibility at an "unprecedented" level. Smart manufacturing is not only a trend but also represents a strong industrial revolution. Vietnam is not out of that trend. Since 2023, Viettel Group has successfully deployed a dedicated 5G network connecting applications for the first smart factory in Vietnam - Pegatron Hai Phong . With 5G infrastructure 10 times faster than 4G, with extremely low latency of only 1-5ms, extremely high connection density and technology mastery, Viettel Enterprise Solutions Corporation has developed a comprehensive 5G2B (5G to Business) ecosystem including separate solutions for each area in the smart factory, from production lines, warehouses to executive offices....

Separate solutions for each area in the smart factory, from production lines, warehouses to executive offices.

Removing bottlenecks of smart manufacturing To build a smart factory, connectivity is the first bottleneck. In the manufacturing sector, the inability to continuously connect a large number of devices not only reduces productivity but also potentially causes great economic losses due to errors or incidents. Low connection speeds cause advanced technologies such as computer vision or AI servers to encounter many obstacles during operation.... The birth of Viettel's 5G network has solved these "pain points" to the maximum. With wide coverage, the 5G network helps eliminate "holes" inside the factory, ensuring smooth connection. With outstanding advantages in broadband, extremely low latency and transmission speed as well as super high stability compared to 4G and wifi, 5G solves the problem of connecting extremely high-density devices such as machines, IoT sensors, cameras, etc. associated with processes and operations in ensuring safety and security, production operations, warehousing, logistics and connecting production lines and operating systems associated with real-time input data. In smart factories, the application of product quality inspection solutions via 5G connection helps transmit large numbers of high-quality 4K, 8K images and process AI analysis at the edge, improving the product defect detection rate to over 99%. The low latency of 5G connection combined with image processing at the edge also helps shorten product completion time, thereby increasing factory productivity. Inventory management and the transportation of goods in the factory between workshops are also automated thanks to AGV/AMR robots. Robots can move flexibly between areas in the factory over a wide range at high speed, helping to reduce labor costs and reduce work-related accidents by up to 25% compared to traditional methods. In terms of overall management, the 5G hyper-connected infrastructure also allows the factory production control center to continuously monitor all production activities, factory safety and security, track production data from workshops in real time, and provide instant warnings on the dashboard system. With machines, each device being able to "talk" about its own status through IoT sensors will help detect technical problems early and repair them remotely, thereby reducing machine downtime that causes production interruptions, saving maintenance costs and increasing equipment life. In addition, remote training and support thanks to 5G-connected AR glasses by technicians with near-zero latency also helps solve complex problems 25% faster. With practical solutions, Viettel shows that the 5G2B application ecosystem will be the foundation to promote a comprehensive revolution in the manufacturing sector, thereby helping Made in Vietnam products improve their global competitiveness.

![[Photo] President Luong Cuong receives delegation of the Youth Committee of the Liberal Democratic Party of Japan](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/8/22/2632d7f5cf4f4a8e90ce5f5e1989194a)

![[Photo] Prime Minister Pham Minh Chinh chairs the conference to review the 2024-2025 school year and deploy tasks for the 2025-2026 school year.](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/8/22/2ca5ed79ce6a46a1ac7706a42cefafae)

Comment (0)