Even though it's almost lunchtime, the sound of machinery and busy footsteps still echo inside the production area of Thanh Nhan TNE (Dong Hoa ward, HCMC).

Workers are urgently loading completed medical equipment onto trucks, in time to deliver it to hospitals and clinics that have pre-ordered it.

Finished medical lamps are loaded onto trucks for transport to hospitals and clinics (Photo: Hoang Le).

19-year-old student recklessly borrows money to produce medical lamps

“This is an infrared hump lamp, which has the effect of warming, reducing pain and increasing blood circulation at the site when the doctor examines the patient. We have been producing it for decades. And that is an eye test lamp, with a reading distance of up to 5 meters, trusted by many large hospitals,” Mr. Tran Quang Minh, Chairman of the company, proudly introduced the product to Dan Tri reporters .

He said that to have a factory of more than 2,000 square meters with dozens of workers, the unit has come a long way of more than 3 decades. And for him, the desire to make high-quality medical products still burns as strong as ever.

Looking back through his memories, Mr. Minh said that in the early 90s of the last century, there were almost no medical equipment produced in Vietnam, the market mainly consumed imported goods from Eastern Europe.

Witnessing the shortage of the country's healthcare system, affecting people's healthcare, young man Tran Quang Minh at that time - although only a first-year student majoring in Electrical Engineering, Ho Chi Minh City University of Technology - had the idea of how to produce medical equipment himself, starting with examination lamps.

Mr. Tran Quang Minh (in white shirt) carefully checks from the initial production stage to the completed medical lamp at the factory (Photo: Hoang Le).

The young man quickly outlined a business plan. He researched information himself, connected with many experts to master technical issues, and boldly borrowed a large amount of money from the bank to invest in machinery and equipment. In 1994, Thanh Nhan TNE medical lamp factory was born, with an initial capital of less than 1 billion VND and only 5 employees.

“At that time, the domestic medical equipment manufacturing industry was still very young, and trust in products made by Vietnamese people was not high. To survive, we initially sought out suppliers for medical lamps, then directed them to produce according to our own designs.

We determined to make products that are both highly technical and aesthetically pleasing, made of good materials like Western products, but at competitive prices.

Gradually, some health departments used and confirmed the quality of our products. With 5-7 workers initially making dozens of light bulbs per day, the company recruited many times more and expanded the production area strongly," said Mr. Minh.

When market demand increased and the company gained a foothold, it boldly invested in billion-dollar production lines and researched and produced a series of new products.

Thanh Nhan TNE's medical lamps have been exported to several Southeast Asian countries (Photo: Hoang Le).

In recent years, in addition to the domestic market, medical lamps "made in Vietnam" through inland waterways and roads have been present in Laos, Cambodia, and Myanmar, even serving 80-90% of the needs of neighboring countries.

“From scratch, we are a pioneer in manufacturing medical equipment lamps in Vietnam. But compared to developed countries, Vietnamese enterprises are still far behind.

If we want to develop with great momentum, to catch up and have an international position, we need to have proper investment. I think Vietnam should establish an association specializing in the production of medical equipment, so that businesses can sit together and discuss the issue of self-sufficiency in the production line.

Second, the State needs to consider the medical equipment manufacturing sector as a key industry to have more preferential policies on taxes, production locations, loan interest rates, etc. to further support businesses.

In addition, it is necessary to invest in developing strong production of personal and family medical equipment. After the Covid-19 pandemic, we have clearly seen the importance of products such as blood pressure monitors and respiratory support machines...", said Mr. Tran Quang Minh.

100 million blood collection tubes and the first “made in Vietnam” safe catheter

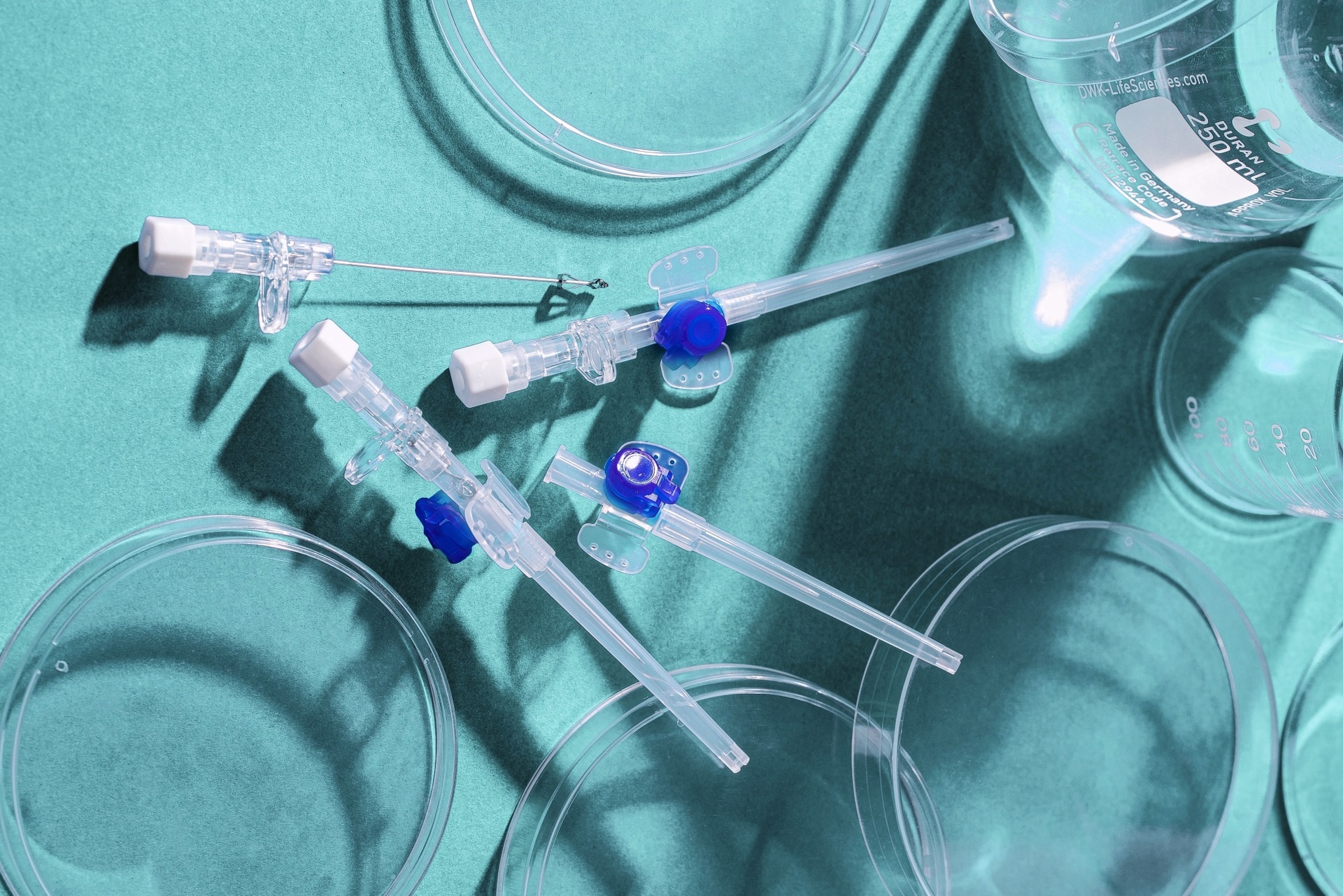

"Every year, Vietnam consumes billions of common blood collection tubes, but we have not strictly controlled the uniformity, quality of chemical spraying, and cleanliness," said Ms. Le Ngoc Thuy Anh, Deputy Director of Wembley Medical Factory Joint Stock Company (Ho Chi Minh City High-Tech Park).

According to her, testing is the first and important step in diagnosing a disease, providing optimal treatment in terms of time and cost for the patient. Diagnosis from testing greatly affects the doctor's decision... Therefore, high-quality blood collection tubes are needed.

Inside Wembley Medical's European standard medical equipment production line (Photo: NVCC).

In 2020, the company started producing blood collection tubes on a new technological line. Within 2 years, 100 million common blood collection tubes were put on the market.

However, when the market stabilized, the unit switched to researching vacuum blood collection tubes - a type of device that has been applied in developed countries since the 1980s in clinical testing.

“Since the 1980s, developed countries have switched to using vacuum tubes in clinical testing procedures. This is a revolutionary medical innovation, with many advantages, such as reducing the risk of hemolysis and eliminating the risk of microscopic blood clots, reducing pain, creating a sense of comfort, saving time and effort…

But in Vietnam, the rate of using this tube in treatment is less than 10%. Although the price is higher than traditional products and medical facilities are not used to using it, we accept the risk of producing European standard vacuum blood collection tubes.

The company believes that when this product is widely used, it will reduce final testing costs, speed up the testing modernization process and contribute to unifying the nationwide testing results," Ms. Le Ngoc Thuy Anh shared.

Safe intravenous catheters and blood collection tubes manufactured at Ho Chi Minh City High-Tech Park (Photo: NVCC).

By 2024, the company will continue to install a safe catheter production line that meets international standards, aiming to reduce costs for patients and increase safety for medical staff during use. The unit is also continuing to research, transfer technology and plans to add a number of new medical products to the catalog.

Ms. Le Ngoc Thuy Anh believes that the potential for developing domestic medical equipment is real, but comes with many challenges. Many businesses are still limited in capital, while the rapid pace of technological innovation results in short product life cycles.

The application of the “low-cost” bidding method does not encourage in-depth investment and high-tech application. In addition, the relationship between medical equipment manufacturers and bidders also needs to be more equal in terms of contracts, delivery and payment.

Lessons of "three-legged stool" to reach out to the world

Talking to Dan Tri reporter , Mr. Truong Hung, Vice President of Ho Chi Minh City Medical Equipment Association shared that Vietnam is about to enter the population aging stage, requiring the need for health care for the elderly and medical development in nursing homes.

Mr. Truong Hung, Vice President of Ho Chi Minh City Medical Equipment Association (Photo: NVCC).

Vietnam currently has more than 2,000 hospitals serving 100 million people, of which 90% are public hospitals. Every year, our country imports more than 2 billion USD of medical supplies and equipment from abroad. The healthcare market grows 10-15% each year.

According to statistics from the World Health Organization (WHO), there are currently more than 20,000 medical equipment products on the market. With such a large and diverse number of products, opportunities are always open for medical equipment manufacturing enterprises.

The Vice President of the Ho Chi Minh City Medical Equipment Association said that in order for the Vietnamese medical equipment industry to reach out to the world, it is possible to apply the development lessons of the "three-legged stool" model ( Government - School - Company) of some Asian countries.

Specifically, the Government funds universities to research topics proposed by medical equipment companies. These research projects, once completed, will be sent directly to domestic high-tech zones for production. Sometimes companies overlap in products, but this increases competition, pushing the quality of medical equipment higher.

According to Mr. Truong Hung, in the past few years, there have been Vietnamese enterprises investing in the production of eye crystals, heart stents, angioplasty balloons... with international standard production lines, but have encountered many difficulties in bringing products to consumers, for many reasons.

In addition to the policy not fully supporting domestic products, there is also a fear of Vietnamese products from the medical team treating them...

Last June, the Ambassador Extraordinary and Plenipotentiary of Pakistan to Vietnam visited the factory producing vacuum blood collection tubes and safe intravenous catheters in Ho Chi Minh City High-Tech Park.

Ambassador Extraordinary and Plenipotentiary of Pakistan to Vietnam (in blue vest) visits a medical equipment factory in Ho Chi Minh City High-Tech Park (Photo: NVCC).

Pakistan wishes to import healthcare products from the factory in the future, showing the potential of the Vietnamese medical equipment industry to reach out to the world.

“Over time, the previous "self-imposed" bidding mechanisms for medical equipment are gradually being loosened, making it easier for many high-quality machines to enter hospitals.

On the business side, the Association hopes that when you have mastered the production of high-tech medical equipment, you will boldly promote your products.

Currently, the Ho Chi Minh City Investment and Trade Promotion Center (ITPC) has a program to support businesses to participate in international exhibitions. This is a favorable condition to help the Vietnamese medical equipment industry see the world," Mr. Truong Hung expressed his hope.

Source: https://dantri.com.vn/suc-khoe/chiec-den-gu-ong-lay-mau-va-bai-hoc-de-thiet-bi-y-te-viet-vuon-ra-the-gioi-20250821145701272.htm

![[Photo] Prime Minister Pham Minh Chinh chairs the conference to review the 2024-2025 school year and deploy tasks for the 2025-2026 school year.](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/8/22/2ca5ed79ce6a46a1ac7706a42cefafae)

![[Photo] President Luong Cuong attends special political-artistic television show "Golden Opportunity"](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/8/22/44ca13c28fa7476796f9aa3618ff74c4)

![[Photo] President Luong Cuong receives delegation of the Youth Committee of the Liberal Democratic Party of Japan](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/8/22/2632d7f5cf4f4a8e90ce5f5e1989194a)

Comment (0)