From 15 million VND that his parents borrowed to start a business, Mr. Nguyen Van Nghia has now become the General Director of a Vietnamese company participating in the supply chain of components for many multinational corporations.

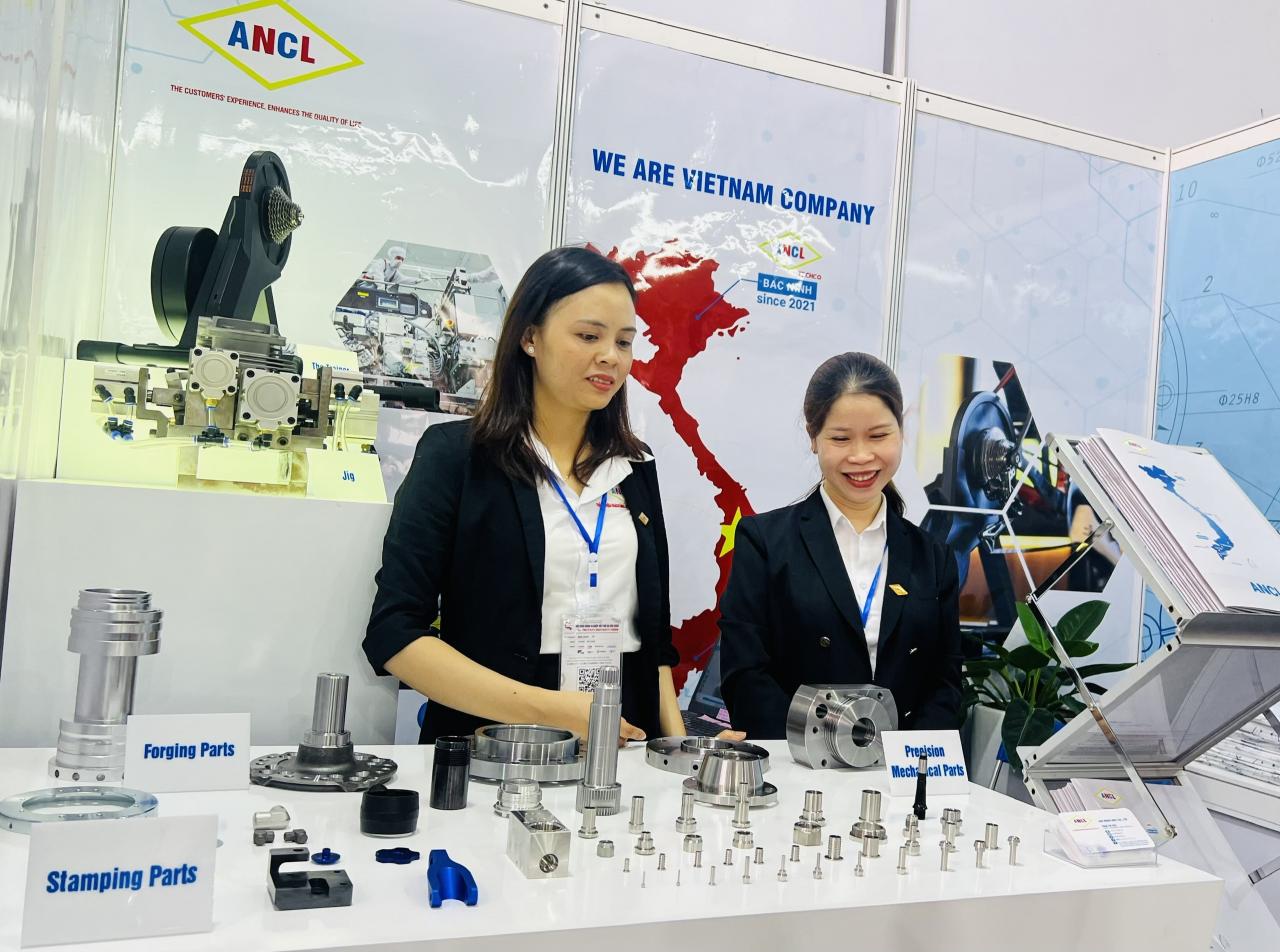

The booth of Anh Nghia Company Limited (ANCL) at the recent international exhibition in Hanoi attracted much attention because of the very large backdrop displaying an image of a map of Vietnam and the words "We are Vietnam Company" (PV).

ANCL's impressive booth at a recent international exhibition in Hanoi.

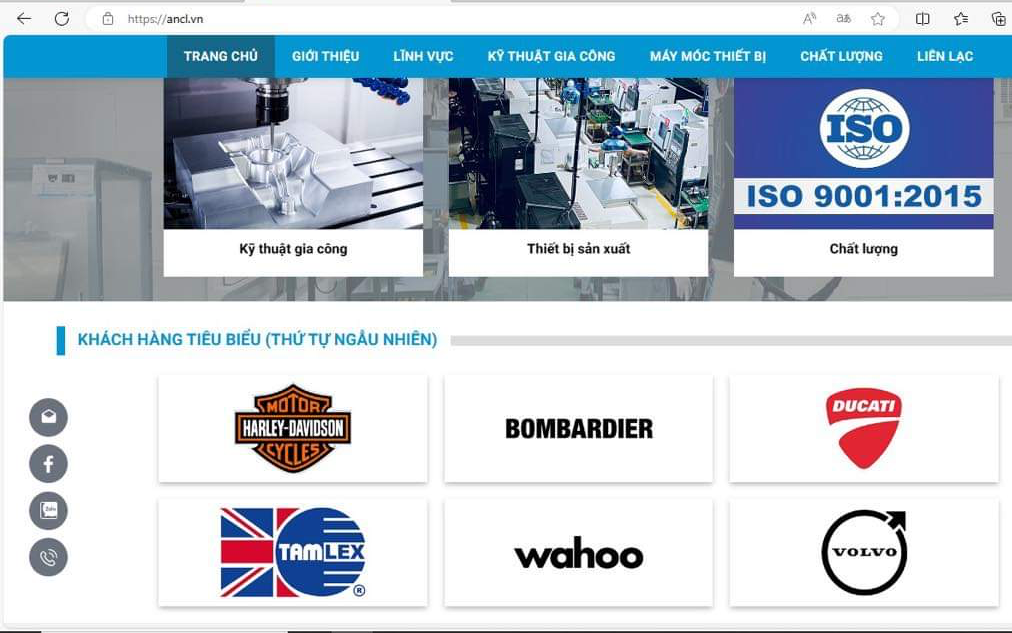

Visiting the company's website to learn more, we found it hard to believe that the customer introduction section had big names such as: Harley Davidson - a famous American motorcycle brand; Ducati - the leading Italian motorcycle brand; Bombardier - a Canadian business jet manufacturer; Volvo - the world's leading car brand in Sweden...

We contacted Mr. Nguyen Van Nghia, General Director of ANCL to learn more about this Vietnamese enterprise.

Start a business with 15 million VND loan

In 2004, Vietnam’s mechanical engineering industry was not as developed as it is now. Very few enterprises mass-produced mechanical components in large quantities. Foreign direct investment (FDI) enterprises with assembly plants in Vietnam mostly had to import components from abroad.

With a passion for mechanics and a desire to contribute to the development of the country's supporting industry, Mr. Nguyen Van Nghia decided to establish ANCL, a business specializing in precision mechanics.

“Setting up a business at that time was quite a bold decision for me,” Mr. Nghia recalled.

Mr. Nguyen Van Nghia, General Director of ANCL.

Due to difficult family circumstances, the family left their hometown of Nam Dinh to go to the South to do new economic activities. The father worked as a security guard for a tobacco factory, so having capital to buy machinery to start a business was a very difficult problem for Nguyen Van Nghia.

“At that time, after graduating from college, I spent about 1 year working as a worker for VPIC Group - an FDI enterprise. It was during my time as a worker, witnessing the situation that FDI enterprises always lacked imported components for production and assembly, that I came up with the idea of establishing a component supply factory. However, without any savings, I had to find every way to convince my parents to borrow money to help me buy machinery, about 15 million VND. The early days of starting a business were truly difficult, lacking everything from capital to experience, information, technology…”, the founder of ANCL said.

With great determination, ANCL's production facility was quickly established. The first customer was the FDI enterprise where Mr. Nghia used to work.

“When I was still cycling to school (in 1997), my friend and I often joked with each other: “If only we could win a lottery ticket, we would be able to eat it all our lives.” The jackpot prize of the lottery ticket at that time was 50 million VND, after tax, the remaining amount was 45 million VND. And the first order, the first invoice I issued to a customer was worth 34.5 million VND, almost achieving my dream of winning the lottery,” Mr. Nghia laughed as he shared an interesting memory related to his first order.

Invest in R&D to make difficult products

After nearly 20 years of manufacturing discrete components according to customer designs in the mid-range segment, the founder of ANCL realized that if the business only processes according to customer requirements, the revenue, profit and value of Vietnamese businesses will only be low. If the business model is not transformed, many risks will be encountered.

Therefore, ANCL decided to invest in human resources and technology to penetrate into difficult product segments. In 2021, ANCL Techco was born, and R&D (research and development) activities were further promoted.

Looking at the system of machinery and modern production lines of ANCL, it can be seen that the "general manager" has invested heavily.

Mr. Nghia said that the total investment capital for current machinery and equipment is more than 5 million USD. However, "it is worth the money", machines with high automation technology (such as milling machines) will generate great revenue and value because they can create products with high difficulty, meeting the requirements of large corporations, such as components in the semiconductor, automobile, medical, oil and gas, sports industries, etc.

Having been a customer of ANCL for about 2 years now with products of components for electric bicycles, motorbikes, engine pipes, etc., and having directly visited ANCL's factory in Dong Nai, Mr. Nguyen Van Ninh, Founder of GDC Vietnam Joint Stock Company, said: "Before going to Dong Nai, our group imagined ACNL as a Vietnamese company, so we only set up a small factory with a few machines. After witnessing it with our own eyes, everyone had the same opinion: Beyond imagination, we did not think a Vietnamese company could invest so systematically."

“Later, GDC's staff often went to work at ANCL's factory in Bac Ninh, including production management, quality management, overall management... Everyone commented that Mr. Nghia's team was very professional,” Mr. Ninh added.

Possessing favorable conditions of relatively good machinery and equipment, combined with a team of highly skilled technicians, ANCL gradually accumulates experience, improves its ability to meet strict requirements on product quality, and gradually participates in the supply chain for many famous multinational corporations.

ANCL's typical customers include many multinational corporations.

“Although we are only the second supplier to large corporations such as Harley Davidson, Ducati, Bombardier, Volvo, etc., we still have to undergo strict evaluation before becoming a supplier in their supply chain. We have to meet many difficult requirements regarding system processes, standards, capacity, etc. After many difficulties, when we upgrade our qualifications, the orders will be stable. ANCL learns a lot about professionalism from these multinational corporations. The strategic and in-depth companionship of multinational enterprises is also a great advantage for Vietnamese small and medium enterprises,” Mr. Nghia continued the story.

Currently, ANCL’s product portfolio includes about 1,000 products in the form of separate components and small components. Particularly noteworthy are some completed products with the “Make in Vietnam” brand such as Trainer - a sports equipment application with simulated game software.

Not only meeting domestic customer needs, Vietnamese precision mechanical enterprises also have about 10 types of products exported to international markets.

A customer in the UK once emailed to express their satisfaction and promised to send their engineers to Vietnam to work with the ANCL team.

Frankly acknowledging the competitiveness of ANCL’s products, General Director Nguyen Van Nghia assessed himself: “The strengths of our products are durability and stable quality. However, to further enhance our competitiveness in the international market, we will continue to improve productivity, streamline production and automate more to have better prices…”.

Pride of Vietnamese brand

Starting out as a worker for FDI enterprises, then becoming their supplier, Mr. Nguyen Van Nghia soon formed the way of thinking and working of a global enterprise.

ANCL has a modern system of machinery, equipment and production lines.

“I am very impressed with ANCL in the way they manage. Although ANC's scale is not equal to that of FDI enterprises, the way they manage data, product information, etc. has both the meticulousness of the Japanese and the transparency of European enterprises. In particular, ANCL has a more human-oriented working mindset. From small things like toilets, cafeterias, etc., everything is very neat. When I interacted with employees working in ACNL's departments, everyone's face was very happy,” the founder of GDC Vietnam Joint Stock Company shared his personal feelings.

With the desire to become a leading enterprise in the mechanical engineering industry, the “general manager” of ANCL spends a lot of time and effort studying more about globalized business, proactively participating in international exhibitions in countries with the most developed mechanical engineering industries in the world such as Germany, the US, Japan, etc. The ANCL brand is increasingly known by multinational enterprises.

“Many times when we participated in international exhibitions in the US and Germany, customers asked ANCL if it was a Japanese or Vietnamese enterprise. Perhaps it was because we have a bit of a Japanese business style, and work quite professionally. Participating in an international exhibition in Hanoi recently, we were very proud to be a Vietnamese enterprise. In addition to avoiding confusion, we wanted to confidently affirm our Vietnamese brand, so we designed the backdrop of our booth with a prominent image of a map of Vietnam and the words “We are Vietnam Company”, Mr. Nghia explained the idea of honoring Vietnamese brands.

Having worked in the precision mechanical engineering industry for many years, the General Director of ANCL stated that the opportunities and potential for Vietnamese enterprises to “Go Global” are huge. We have had many enterprises successfully exporting to many large economies. There are many opportunities but there is also no shortage of competition and macro-level risks. In a flat world, many things become easier, but many things also become more difficult. To be successful, Vietnamese enterprises need to proactively learn, improve their technological level and management skills; must always maintain confidence, and especially must have business ethics and respect for customers.

With the orientation of "Wherever ANCL's products are, there is ANCL's market boundary", ANCL aims for export value to account for 60 - 70% of total revenue. Currently, this Vietnamese enterprise is continuing to promote marketing activities, structure resources, invest in technological equipment and select appropriate customer segments and products to soon realize the set goals.

In response to the question “Who has had the greatest influence on you personally throughout your career development?”, the ANCL General Director confidently replied: “No one. Taking business ethics as a guiding principle for my career, I always make it difficult for myself within the rules so as not to lose myself.”

Vietnamnet.vn

![[Photo] "Lovely" moments on the 30/4 holiday](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/5/1/26d5d698f36b498287397db9e2f9d16c)

![[Photo] Binh Thuan organizes many special festivals on the occasion of April 30 and May 1](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/5/1/5180af1d979642468ef6a3a9755d8d51)

![[Photo] Ha Giang: Many key projects under construction during the holiday season](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/5/1/8b8d87a9bd9b4d279bf5c1f71c030dec)

Comment (0)