On October 30, in Huong Hoa commune, Tuyen Hoa district, Quang Binh province, tunnel No. 2, 355 m long, under package XL01, the Khe Net Pass railway renovation project was officially opened by the Ilsung - Deo Ca Joint Venture, 2 months ahead of schedule.

On October 30, in Huong Hoa commune, Tuyen Hoa district, Quang Binh province, tunnel No. 2, 355 m long, under package XL01, the Khe Net Pass railway renovation project was officially opened by the Ilsung - Deo Ca Joint Venture, 2 months ahead of schedule.

According to the report from the Contractor Consortium, up to now, the consortium has mobilized 230 engineers, workers, machine operators along with more than 35 specialized machines and equipment, organizing 4 construction teams simultaneously on 2 tunnels. The construction volume of tunnel 1 reached 130 md/580 md and tunnel 2 completed 355 md/355 md. The construction output reached 120 billion VND, exceeding the set progress by 9%.

The representative of the package management board said that the two Khe Net railway tunnels have the characteristics of running along the mountainside, with a thin cover layer, complex and constantly changing tunnel geology, not following the original technical design. To overcome this, the contractor consortium coordinated with the investor and the supervision consultant to closely follow the construction site and propose appropriate reinforcement plans, ensuring safety and quality according to the actual geology.

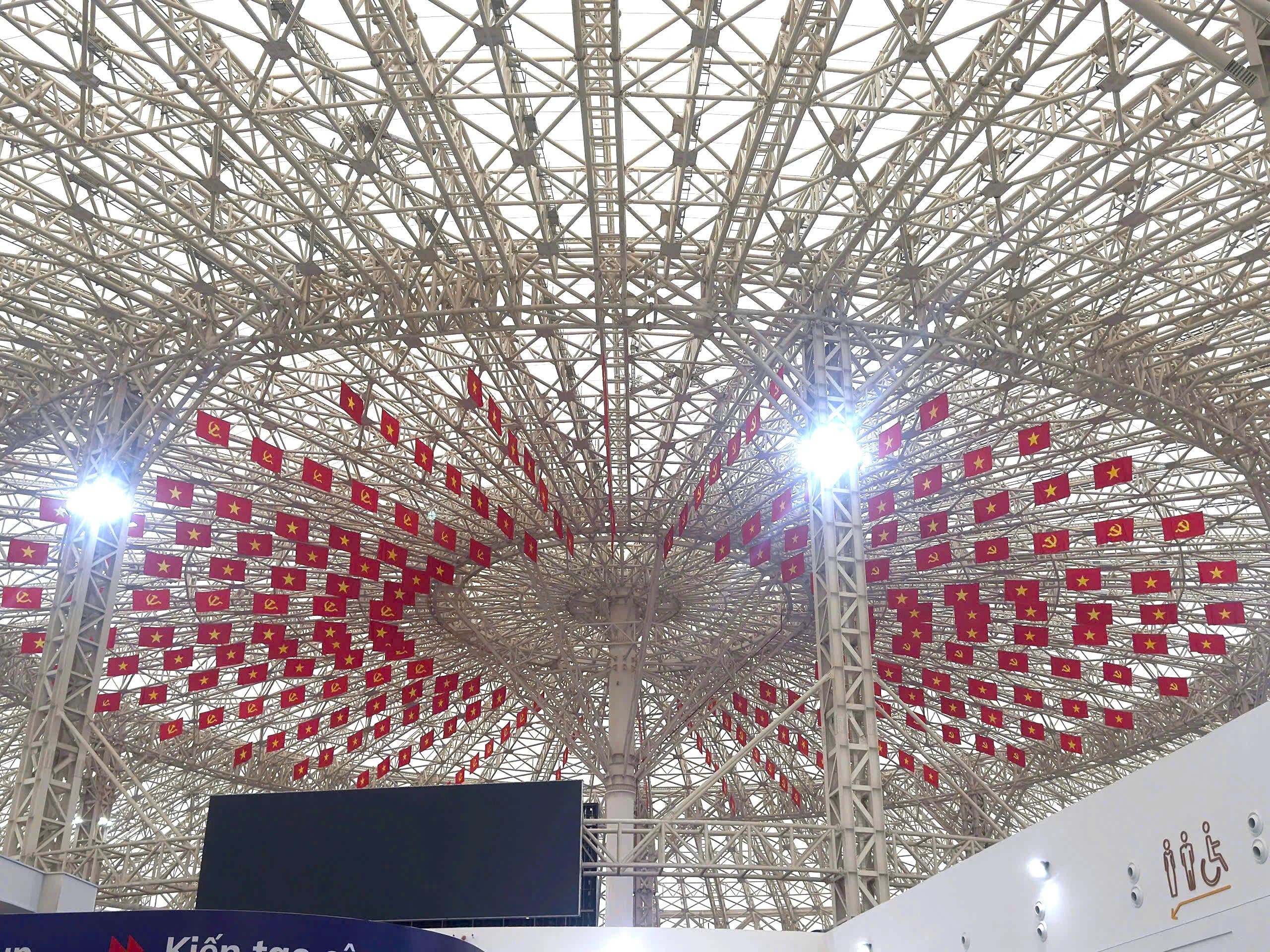

|

| Tunnel No. 2 of the package was dug ahead of schedule. |

In addition, the Management Board has encountered some difficulties due to the land handover being later than originally planned, along with obstacles in leasing land for public roads and finding suitable dumping sites. Specifically, some dumping sites have been planned on agricultural land, causing difficulties in site clearance due to not receiving compensation from the investor.

To ensure the set progress, the contractor consortium has made efforts and proactively proposed construction solutions, promoted internal training to improve labor productivity for engineers and workers, and organized construction in "3 shifts, 4 teams". In addition, the consortium regularly monitors geology to promptly adjust reinforcement measures, ensuring safety and quality of the project. Currently, the difficulties have been basically resolved. The goal is to dig tunnel 1 before April 2025, pour concrete for the shell and complete tunnel 1 before November 2025 and tunnel 2 before September 2025.

Mr. Nguyen Duy Song, Director of the XL1 Package Management Board, said that today's tunnel opening ceremony is an important milestone, making it more convenient to transport fuel, goods, and construction workers, speeding up the project's progress.

Mr. Song added that Khe Net Railway Tunnel applied NATM technology in construction. This technology has been mastered and improved by Deo Ca, applied in many road tunnel projects that Deo Ca has been and is implementing.

It is known that the XL01 package belongs to the Khe Net Pass Railway Improvement Project, Hanoi - Ho Chi Minh City Railway Line, constructing 2 railway tunnels with a total length of 935 m, with a construction period of 23 months, carried out by the joint venture of Ilsung Company - Deo Ca Group. Of which, tunnel 1 is 580 m long, tunnel 2 is 355 m long. This is an important package of the project, implemented with ODA capital, located in Huong Hoa and Kim Hoa communes, Tuyen Hoa district, Quang Binh province.

Upon completion, the project will not only contribute to reducing traffic congestion and improving freight and passenger transport capacity, but also create momentum for the socio-economic development of the region, helping to strengthen connectivity between regions, and positively contributing to the national transport network.

For NATM technology, the core of this technology is “digging to where, processing to where” to create self-balance, stability of the tunnel structure. In which, the tunnel is processed with a steel dome and then sprayed with solidified concrete to create geological stability for the tunnel immediately after drilling. At the same time, engineers will conduct inspections, monitor the deformation and convergence of the tunnel geology to verify the reasonableness in order to come up with a drilling solution.

This technology aims to ensure a safe environment for workers while facilitating future tunnel operations. To operate this technology, the site must have a full range of drilling machines, concrete spraying machines, excavators, and material transport vehicles.

Source: https://baodautu.vn/quang-binh-thong-ham-so-2-du-an-cai-tao-duong-sat-khe-net-d228726.html

![[Photo] President Luong Cuong receives delegation of the Youth Committee of the Liberal Democratic Party of Japan](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/8/22/2632d7f5cf4f4a8e90ce5f5e1989194a)

![[Photo] Prime Minister Pham Minh Chinh chairs the conference to review the 2024-2025 school year and deploy tasks for the 2025-2026 school year.](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/8/22/2ca5ed79ce6a46a1ac7706a42cefafae)

![[Photo] President Luong Cuong attends special political-artistic television show "Golden Opportunity"](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/8/22/44ca13c28fa7476796f9aa3618ff74c4)

Comment (0)