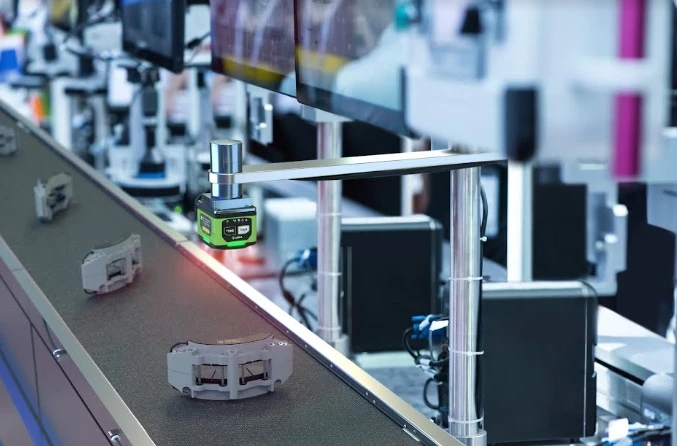

DNVN - Manufacturers often struggle to use data effectively, so they need to apply AI (artificial intelligence) and other digital technology solutions to create a flexible, optimal production environment.

Driving growth with AI and new technology

Zebra Technologies Corporation has just released the results of its 2024 Manufacturing Vision Study. The study found that globally, 61% of manufacturers expect artificial intelligence (AI) to drive growth by 2029, up from 41% in 2024. In the Asia- Pacific (APAC) region, 68% of manufacturers expect AI to drive growth by 2029, up from 46% in 2024.

The rise in AI adoption, coupled with 92% of global respondents and 87% in the Asia-Pacific region prioritizing digital transformation, demonstrates the desire of manufacturing businesses to improve data management processes and deploy new technologies to enhance visibility and quality throughout the production process.

Although manufacturing businesses are primarily prioritizing digital transformation, approximately 30% to 40% of survey respondents globally and in the Asia-Pacific region acknowledged that the process faces many difficulties and obstacles, including costs and labor resources, scaling technology solutions, and the convergence of information technology and operational technology (IT/OT).

“Manufacturers often struggle to use data effectively, so they need to adopt AI and other digital technology solutions to create a flexible, optimized manufacturing environment,” said Christanto Suryadarma, Vice President of Sales for Southeast Asia (SEA), Korea and Channel Distribution for CA-TBD, Japan excluding China (APJeC), Zebra Technologies. “Zebra helps Vietnamese manufacturers apply technology in new ways to automate and enhance workflows, building a connected factory where technology supports humans at scale.”

Zebra provides manufacturing businesses with strategic insights and technology to drive the growth of connected factories by increasing monitoring visibility, optimizing quality, and empowering the workforce.

While nearly six in 10 leading manufacturing companies (57% globally, 63% in CA-PTB) expect to increase visibility across the entire manufacturing process and supply chain by 2029, about one-third of business leaders (33% globally, 38% in CA-PTB) say the lack of alignment between IT and operational technology in selecting investment projects is the biggest barrier to digital transformation.

Zebra research shows manufacturers are shifting their growth strategies by integrating and empowering their workforce with AI and other technologies to transform manufacturing operations and build a skilled workforce over the next five years.

Technology tools being deployed by manufacturing leaders include enterprise tablets (51% globally, 52% in CA-TP), wearables (55% globally, 53% in CA-TP), and workforce management software (56% globally, 62% in CA-TP). Additionally, 6 in 10 manufacturing companies (61% globally, 65% in CA-TP) plan to use wearables to empower their workforce.

Applying artificial intelligence (AI) and other advanced Zebra technologies such as enterprise computer terminals (ET60, MC9400, and TC53e); data collection solutions (DS3600-XR, DS4678-XD, and DS55); asset tracking solutions (ZT231, ZT421/ZT411, and Zebra VisibilityIQ Foresight); RFID solutions (FXR90); and Fixed Industrial Scanning and Machine Vision solutions, is critical to increasing productivity, improving quality, and streamlining operations.

Manufacturing business leaders’ technology deployment plans will address these challenges. Over the next five years, many plan to deploy robotics (65% globally, 72% in APAC), vision surveillance (66% globally and APAC), radio frequency identification (RFID) (66% globally, 72% in APAC), and fixed industrial barcode scanners (57% globally, 62% in APAC).

Think big but act small

According to Zebra, Vietnam has always set ambitious targets for the manufacturing sector, with an expected contribution of 30% to the total GDP. The sector’s contribution to GDP will increase by more than 8.5% each year and labor productivity will increase by 7.5%. To achieve these targets, Vietnamese businesses must meet the need to retrain and equip their workforce with new skills to remain competitive.

Sharing with Vietnamese Enterprises , Zebra representative, Mr. Aik Jin Tan said: "Usually, we will advise customers to "Think big but act small", which means we want them to imagine what their destination is. Let's determine the appropriate field, where we should start, small. For example, when we have a market that wants to digitize the factory floor or in the factory floor we want to automate but in the factory floor there are also smaller parts, let's start from a small scale, verify the idea, called Proof of Concept and after success, we will continue to replicate and expand it to achieve the overall goal.

The advantage of Zebra’s solution is that if we want to implement, for example, a real-time location capture solution, we have a solution that meets your needs. If you feel that we need to start small, just do basic digitization, we have a fixed barcode solution. Of course, even if you just want to implement barcodes, we have a solution that helps you start from the beginning. If you want to upgrade it further, there is RFID for you to upgrade.

"The next advantage of Zebra's solution is scalability. For example, we want to buy a simple solution now, but in a few years because our orientation is to deploy RFID, for example, we allow scalability. Now you only buy a regular barcode printer, you let us know that in a few years you want to deploy RFID and we help you expand your current solutions to become an RFID system. After 2 years, for example, we see that your factory is ready for RFID, Zebra can completely help with that. That is how Zebra provides solutions, bringing value to customers throughout the entire process of deploying the 4.0 industrial revolution", Zebra representative shared more.

Hoang Phuong

Source: https://doanhnghiepvn.vn/kinh-te/doanh-nghiep-san-xuat-gap-kho-trong-doi-moi-sang-tao-cach-nao-de-thao-go/20240823041149816

Comment (0)