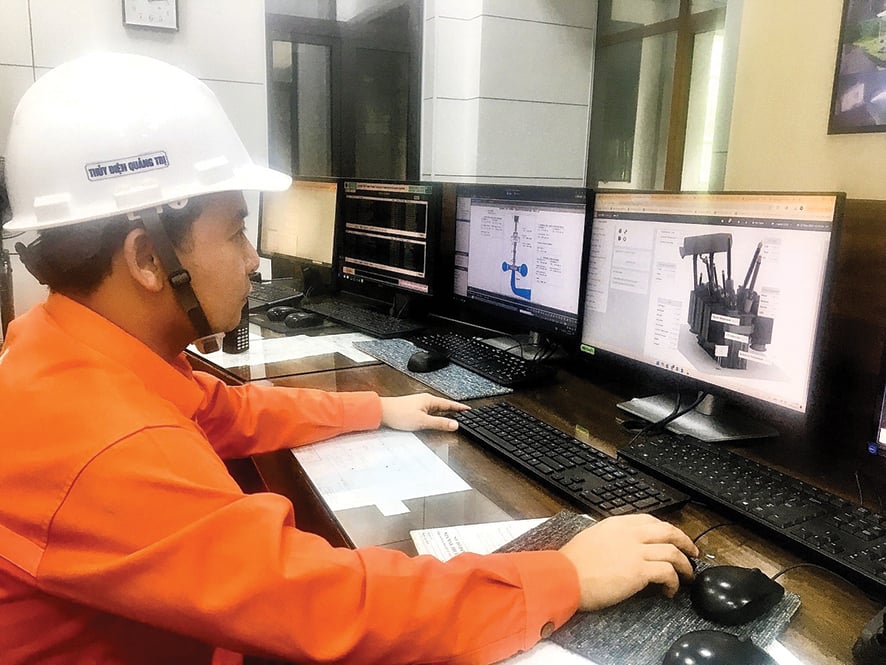

Operators are checking the MBA online monitoring parameters via online monitoring software - Photo: TN

Over the years, Quang Tri Hydropower Company has continuously applied science and technology and promoted digital transformation to improve labor productivity, optimize costs and contribute to ensuring energy security. The application of science and technology to production and business activities plays an important role in improving operational efficiency, reducing costs and optimizing operations. The company always complies with the regulations and rules in science and technology and digital transformation activities of Power Generation Corporation 2. Fully participate in science and technology conferences, introduce products of famous technology companies such as Andrizt, GE, Hitachi... to promptly update modern digital products, meeting the company's production and business needs in the digital industrial age.

In the 2023-2024 period alone, the company has invested in installing new technology application systems at Quang Tri Hydropower Plant such as: Generator partial discharge monitoring system, transformer online monitoring, generator vibration monitoring... These are support tools, serving the monitoring, analysis and diagnosis of equipment status in real time with the aim of early detection of defects and damage to promptly take measures to prevent possible incidents... Equipped with 3D SCAN machine to collect 3D data of complex shaped parts, allowing accurate modeling.

On December 22, 2024, the Politburo issued Resolution No. 57-NQ/TW on breakthroughs in science, technology, innovation and national digital transformation. Vietnam Electricity Group and Power Generation Corporation 2 have also issued many directives on innovation, applying science and technology to become a cultural feature contributing to improving capacity, production efficiency and labor productivity. |

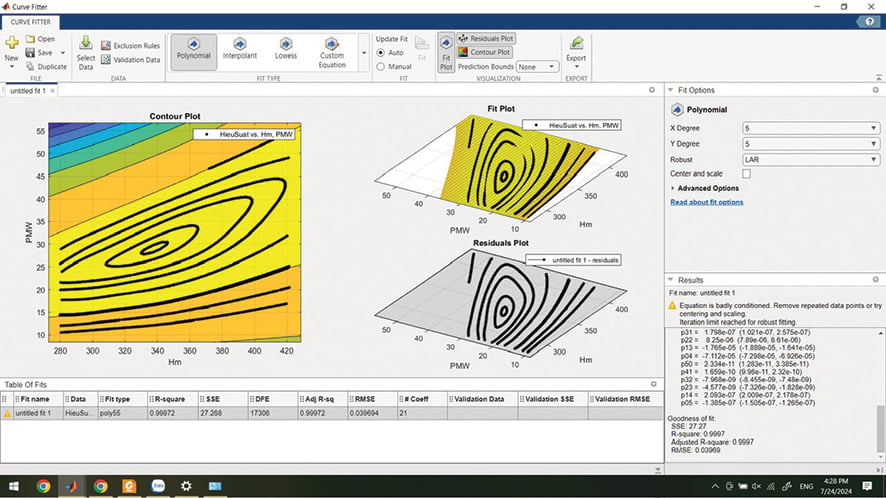

In 2024, the company applied software to digitize the characteristic curve of the generator turbine and forecast the optimal power generation capacity corresponding to the actual water level that Son La Hydropower Company transferred in the software that applied artificial intelligence algorithms to forecast the optimal power generation capacity. The company is continuing to research, deploy, and optimize the software after the software trial period.

Training on artificial intelligence (AI) technology to improve the efficiency of hydropower plant operations - Photo: TN

The digitization of equipment information of the entire factory on the technical management software has performed data entry and digitization including more than 5,000 devices, fully updated operating context, RCM analysis table of more than 47 systems.

Defect data, repair information, operating parameters... have been applied to the software. Applying digital information technology to manage construction land, construction protection corridors, searching and identifying construction landmark systems. Building digital software to measure the factory's self-consumed electrical system, applying QR-Code to digitize data of equipment with strict safety requirements...

Therefore, in 2024, 2 solutions were recognized as initiatives at the Power Generation Corporation 2 level and 7 solutions were recognized at the grassroots level. In particular, the initiatives are rich and diverse in application areas such as digital transformation, automation, finance, etc. The company also deploys science and technology services, inviting leading lecturers in the relay industry from Hanoi University of Science and Technology to train and improve the professional skills of automation for employees of the direct production department and technical management.

Digitizing Turbine characteristics using algorithms on Matlab software - Photo: TN

To complete the goals and tasks of the Science and Technology and Digital Transformation work plan in 2025 and the following years, Quang Tri Hydropower Company continues to raise awareness, make breakthroughs in innovative thinking, encourage creativity, promote the spirit of self-study and learning. Direct production units proactively research, study, supplement knowledge, improve qualifications to grasp and master the technologies and newly equipped equipment systems.

Regularly monitor and analyze data collected from equipped online monitoring systems such as: partial discharge (PD) of H2 generator and online monitoring of T2 transformer, monitoring vibration and islanding of 2 units to serve the management of operation, repair and maintenance effectively; effectively exploit 3D SCAN machine to create accurate digital records, improving work quality.

Strengthening the organization of specialized training courses, improving scientific, technological and digital transformation knowledge for the company's staff. Visiting and studying at other units, participating in conferences introducing solutions of major technology companies to grasp and update new knowledge, research and deploy at the factory. Taking advantage of the application of achievements of science and technology 4.0, especially AI artificial intelligence applications.

Artificial intelligence applications are being developed widely in cyberspace, and their application to work is essential, typically Chat GPT of Open AI Group, Gemini of Google serving in analysis, self-learning, in-depth research... or some other AI applications that are being developed strongly.

Build a data collection system, automatically calculate, synchronize to the website to set up an automatic transmission mode to report unified data to the authorities and focal points that need to report according to the regulations of state management agencies on parameters: rainfall, lake flow, spillway discharge, minimum flow, turbine flow; lake water level, flow forecast data, water transfer flow from Pa Rong lake to Quang Tri lake...

Research on the construction plan of an automatic system to collect data on the operation of the generator, automatically export operating reports; a thermal camera system to automatically measure the temperature of outdoor equipment at the 110kV station and main transformers T1, T2.

Research and build Chatbot to serve factory operators related to science and technology, innovation... Develop a plan to complete information technology infrastructure and ensure information security, ensure safe and sustainable connections, and at the same time promote the application of famous digital products and services in office management and administration.

Lam Khanh

Source: https://baoquangtri.vn/cong-ty-thuy-dien-quang-tri-ung-dung-khoa-hoc-cong-nghe-thuc-day-chuyen-doi-so-193377.htm

![[Photo] Bus station begins to get crowded welcoming people returning to the capital after 5 days of holiday](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/5/4/c3b37b336a0a450a983a0b09188c2fe6)

![[Photo] Vietnam shines at Paris International Fair 2025 with cultural and culinary colors](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/5/4/74b16c2a197a42eb97597414009d4eb8)

![[Photo] General Secretary To Lam receives Sri Lankan President Anura Kumara Dissanayaka](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/5/4/75feee4ea0c14825819a8b7ad25518d8)

![[Video]. Building OCOP products based on local strengths](https://vphoto.vietnam.vn/thumb/402x226/vietnam/resource/IMAGE/2025/5/3/61677e8b3a364110b271e7b15ed91b3f)

Comment (0)