Vietnam Railway Corporation has submitted to competent authorities the Railway Industrial Complex project in Hanoi with a scale of about 250 hectares, with a total preliminary capital of more than 17,500 billion VND - Illustrative photo

According to calculations by Vietnam Railways Corporation (VNR), the entire industry currently has 258 locomotives, 980 passenger cars and more than 4,300 freight cars. By the end of 2025, at least 114 locomotives, 1,472 freight cars and 168 passenger cars will have to be "retired" according to age regulations.

Thousands of train cars and locomotives must be 'retired' by the end of this year

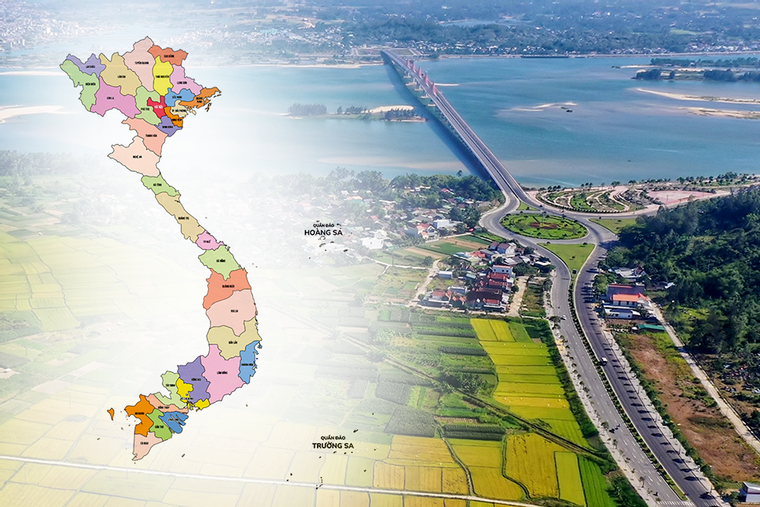

Meanwhile, the Railway Network Plan to 2050 aims to build 25 lines with a total length of more than 6,300 km, including 18 new lines. Urban railways, high-speed railways and local railways alone will require thousands of new power cars, passenger cars and freight cars.

The North-South high-speed railway alone is expected to require 1,100 EMU (Electric Multiple Unit) cars. Urban railways need nearly 1,500 cars. Existing railways and newly electrified lines need hundreds of locomotives, thousands of passenger cars and more than 7,000 freight cars.

The demand for carriages and locomotives is so great, but according to Mr. Hoang Nang Khang, Deputy General Director of VNR , the domestic railway industry is currently only concerned with repairing and replacing old systems, has no export products, and has not been able to produce electric locomotives. The capacity to build new specialized freight carriages is still very limited.

Goal of mastering production technology

Faced with the urgent need from that reality, Vietnam Railway Corporation has submitted to the competent authority the Railway Industrial Complex project in Hanoi with a scale of about 250 hectares, with a total preliminary capital of more than 17,500 billion VND. The goal of forming this complex is to master production technology, gradually localize locomotives and carriages; manufacture components, information - signal - electrification software; and major repair of all railway vehicles.

This complex will include a factory for manufacturing and assembling vehicles - equipment - spare parts; a research and innovation center; a repair and maintenance center; and a system directly connected to the national railway.

"In particular, the complex can receive technology transfer to produce locomotives, carriages under 200 km/h and urban carriages, instead of having to import everything as it does now," said Mr. Khang.

The railway industrial complex will use public investment capital and a part of socialized capital. Of which, public investment capital will focus on connecting lines, technical infrastructure, R&D centers (research and development) and State-supported items. Enterprises will be supplemented with charter capital to build factories, and at the same time, call for socialized participation in production and business in the complex.

Based on the development orientation, VNR proposes the scale of production and assembly capacity each year including 10 diesel locomotives, hybrid locomotives or locomotives using clean energy (PNG, hydrogen); 15 electric locomotives; 50 regular passenger cars; 60 passenger cars with a speed of 160 km/h; 300 freight cars with a gauge of 1,435 mm and 1,000 mm; 200 urban cars...

The complex is expected to have about 20 main functional areas, serving all stages of production, assembly, maintenance and research such as the bogie production area: manufacturing and assembling components such as wheel axles, frames, braking systems, shock absorbers, auxiliary equipment... for locomotives, carriages, EMUs and high-speed trains.

Locomotive assembly area, production of car bodies, car bases; freight car assembly; EMU train assembly; high-speed train assembly: complete assembly of high-speed trains; production of materials, equipment, spare parts...

In addition to the main production areas, the Complex also has supporting functional areas such as training center; Railway technology research center; Train parking lot, washing area, power station, environmental treatment area; Test track; Accommodation area for workers; Logistics center...

To make the project feasible, VNR proposed many specific mechanisms such as: allowing bidding for high-tech packages; applying norms and investment rates referenced from domestic and foreign projects; shortening the environmental assessment time, and clearing the site at once for the entire scale.

The 2025 Railway Law has provisions to promote and encourage the development of the railway industry and transfer of science and technology - Photo: Ve Al

With the existing railway, as soon as the Complex comes into operation, VNR will assemble, manufacture and renovate clean energy diesel locomotives; at the same time produce passenger cars and freight cars.

With urban railway, new line, high speed:

+ Phase 2029 - 2031: Import some locomotives and passenger trains with a speed of 160km/h; assemble electric locomotives and clean energy locomotives; manufacture 160km/h passenger cars; assemble EMU trains for metro; manufacture 120km/h freight cars for the Lao Cai - Hanoi - Hai Phong route.

+ Phase 2031 - 2032: Assemble locomotives, produce EMU trains for urban areas; complete production of passenger cars and freight cars with a speed of 160 km/h.

+ Phase 2032 - 2035: Master the production of passenger cars and freight cars under 160 km/h; assemble electric locomotives; increase the localization rate to 30%.

With the North-South high-speed railway:

+ After 2032: Start assembling high-speed EMU trains under procurement and technology transfer contracts.

+ By 2035: Master assembly technology, localization reaches 20%.

+ Phase 2035 - 2040: Increase localization rate to 50%.

+ Phase 2040 - 2050: Strive to reach 80% and proactively produce domestic materials and spare parts.

According to Mr. Duong Hong Anh, Deputy Director of the Vietnam Railway Authority, the Railway Law 2025 (effective from July 1, 2025) has dedicated a section for the development of the railway industry, with many priority policies. This is an important legal corridor for implementing the railway industrial complex proposed by VNR as well as the foundation for the complex to operate later and attract businesses outside of public investment capital.

To promptly implement the 2025 Railway Law, the Government has directed the Ministry of Construction and the Ministry of Science and Technology to develop 3 Decrees and 2 Decisions of the Prime Minister to implement the provisions of the Law, which will take effect from July 1, 2025.

Specifically: The Decree details the overall technical design, specific and special mechanisms for implementing railway projects (currently issued by the Government in Decree No. 123/2025 dated June 11, 2025); The Decree stipulates the criteria for selecting State-owned organizations and enterprises assigned tasks or Vietnamese organizations and enterprises ordered to provide railway industrial goods and services; The Decree stipulates research, application, and technology transfer in the railway sector.

At the same time, the Ministry of Construction directed the agencies and units under the Ministry to submit to competent authorities to issue a Decree detailing a number of articles and measures to organize and guide the implementation of the Railway Law; 3 Circulars guiding the implementation, to ensure that they take effect at the same time as the Law, which takes effect from January 1, 2026.

Phan Trang

Source: https://baochinhphu.vn/cong-nghiep-duong-sat-made-in-viet-nam-khi-nao-se-hinh-thanh-10225082120220834.htm

Comment (0)