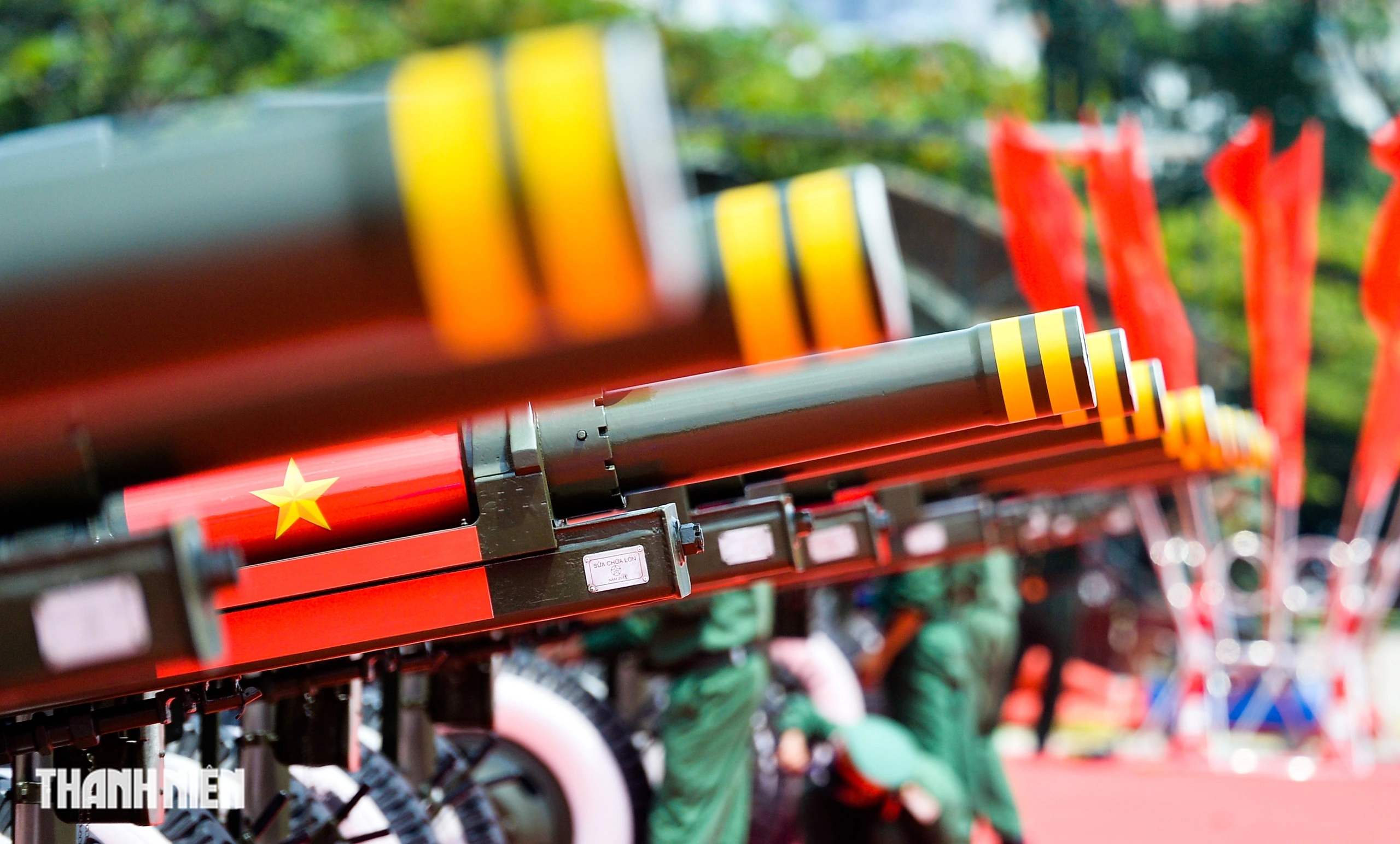

The U.S. ammunition and energy industry is at a crossroads, as the Army invests heavily in ammunition technology and manufacturing capacity.

This includes a strong focus on artillery ammunition, complemented by the simultaneous pursuit of much-needed artillery capability improvements – all aimed at improving the precision long-range artillery firepower that is so desperately needed.

The US is struggling to find ways to improve propellant technology for artillery shell production. Photo: Defense One

But to fully realize this artillery capability, the United States must invest in propellant technology and related manufacturing capabilities to ensure the defense industry can support this increase by producing affordable, accessible, and large-scale domestic nitrocellulose (NC) and propellant.

Unfortunately, America's current industrial infrastructure is ill-suited to producing the advanced energy needed to meet soaring demand and higher artillery performance.

Currently, the most advanced technology and manufacturing are not in American hands. For example, some of the most important artillery propellants are sourced from Canada, creating supply chain risks. The most advanced tank and artillery propellant technologies used in systems around the world are found in allied industrial bases overseas.

The Army Ammunition Plant has been producing US artillery shells for over 50 years. Photo: Alamy

Addressing these shortcomings in domestic technology and manufacturing is critical to enabling U.S. howitzers — as well as tanks and medium-caliber systems — to deliver the increased lethality that U.S. service members need, while ensuring the industrial resilience and magazine depth to win even in prolonged battles.

Today, the United States produces most of its propellants and power domestically at the Radford Army Ammunition Plant in Virginia. In operation since World War II, the Government Owned and Contractor Operated (GOCO) facility is the only facility in the United States capable of producing single-, double-, and triple-base propellants, as well as their constituent components: NC, nitroglycerin, and acids.

However, America's next war will require longer-range, more lethal, more targeted engagements powered by next-generation fuels, and Radford's production capabilities will need to be improved to support this future scenario.

Radford's basic infrastructure (electricity, utilities, wastewater treatment) is in need of extensive modernization, and many of the processes and manufacturing technologies being used are over 50 years old. The plant is experiencing frequent breakdowns and has a serious environmental impact.

Radford was also not fully prepared to produce solvent fuels on a large scale, although the company had longstanding manufacturing capabilities that contributed to sourcing these critical fuels from outside the United States.

Find a Public-Private Partnership Solution

The US is about to launch a modernized facility in North Carolina that will allow Radford to finally produce more of the basic fuel components needed to improve this worrying situation.

This factory is invested in the form of public-private partnership, BAE bears the cost in return for being allowed by the US to use military facilities to research and develop their own military products as a contractor.

BAE System is building a new ammunition manufacturing plant in North Carolina. Photo: BAE System

However, modernization of other aspects of ammunition, such as artillery shells, has progressed more rapidly. It is important that modernization of the fuel industrial base is also accelerated so as not to leave behind a key capability in the firepower ecosystem, which could undermine overall lethality and much-anticipated capability improvements.

In this context, the US Army needs to rebuild its propellant industrial base – both in terms of technology and manufacturing capacity and excellence.

American Rheinmetall Munitions (ARM) is one such company, bringing its expertise, global technology portfolio, and public-private partnerships to U.S. industry. ARM is committed to working with the military to address the technology and manufacturing needs to deliver better and more power.

The Department of Defense 's ammunition industry is facing challenges with capacity, technology, and outdated facilities and processes.

The US energy industrial base and arsenal need to be modernized to produce next-generation munitions and ensure a vertically integrated supply chain.

Source: https://khoahocdoisong.vn/my-loay-hoay-cai-tien-vat-lieu-no-tang-tam-dan-phao-post2149046022.html

![[Photo] An Phu intersection project connecting Ho Chi Minh City-Long Thanh-Dau Giay expressway behind schedule](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/8/21/1ad80e9dd8944150bb72e6c49ecc7e08)

![[Photo] Politburo works with Standing Committees of Lang Son and Bac Ninh Provincial Party Committees](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/8/20/0666629afb39421d8e1bd8922a0537e6)

![[Photo] Prime Minister Pham Minh Chinh receives Australian Foreign Minister Penny Wong](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/8/20/f5d413a946444bd2be288d6b700afc33)

Comment (0)