According to the Wall Street Journal on July 22 , some Boeing planes are left abandoned outside the factory and even in employee parking lots due to lack of interiors or engines. While some other planes are completed and awaiting delivery to China.

The component delays are due to supply chain shortages that have persisted since the Covid-19 pandemic, with seat suppliers unable to meet Boeing’s needs, especially for high-end goods. The company has also had difficulty sourcing temperature-regulating components for its aircraft.

A Boeing 777X test aircraft takes off in Everett, Washington (USA) on June 26, 2024.

With 200 planes grounded, Boeing is losing about $1 billion a month and facing a host of logistical challenges. Moving unfinished jets is difficult, especially those without engines.

This difficult situation comes as the aircraft manufacturer is facing multiple investigations and close supervision from the US Federal Aviation Administration (FAA) following the door button failure on the Boeing 737 Max 9 aircraft on January 5. In addition, Boeing has also had to slow down production to focus on product quality.

Boeing employees said they were working to create more space for the planes while also working to complete them. The company also noted that the storage of the planes would not affect production rates.

Mr. Ron Epstein, aerospace analyst at Bank of America (USA), assessed that Boeing's prospects for aircraft delivery and warehouse clearance are still open.

In a related development, Boeing CEO Stephanie Pope said on July 21 that they are significantly improving the manufacturing and assembly process of the 737 MAX aircraft at the Seattle (USA) factory. According to Ms. Pope, this is a major change for Boeing with the hope of reaching production of 38 737 MAX aircraft per month by the end of this year.

Source: https://thanhnien.vn/boeing-trung-dung-ca-nha-xe-nhan-vien-de-chua-may-bay-dap-chieu-18524072220450123.htm

![[Photo] Prime Minister Pham Minh Chinh chairs the meeting of the Government Party Committee Standing Committee](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/8/23/8e94aa3d26424d1ab1528c3e4bbacc45)

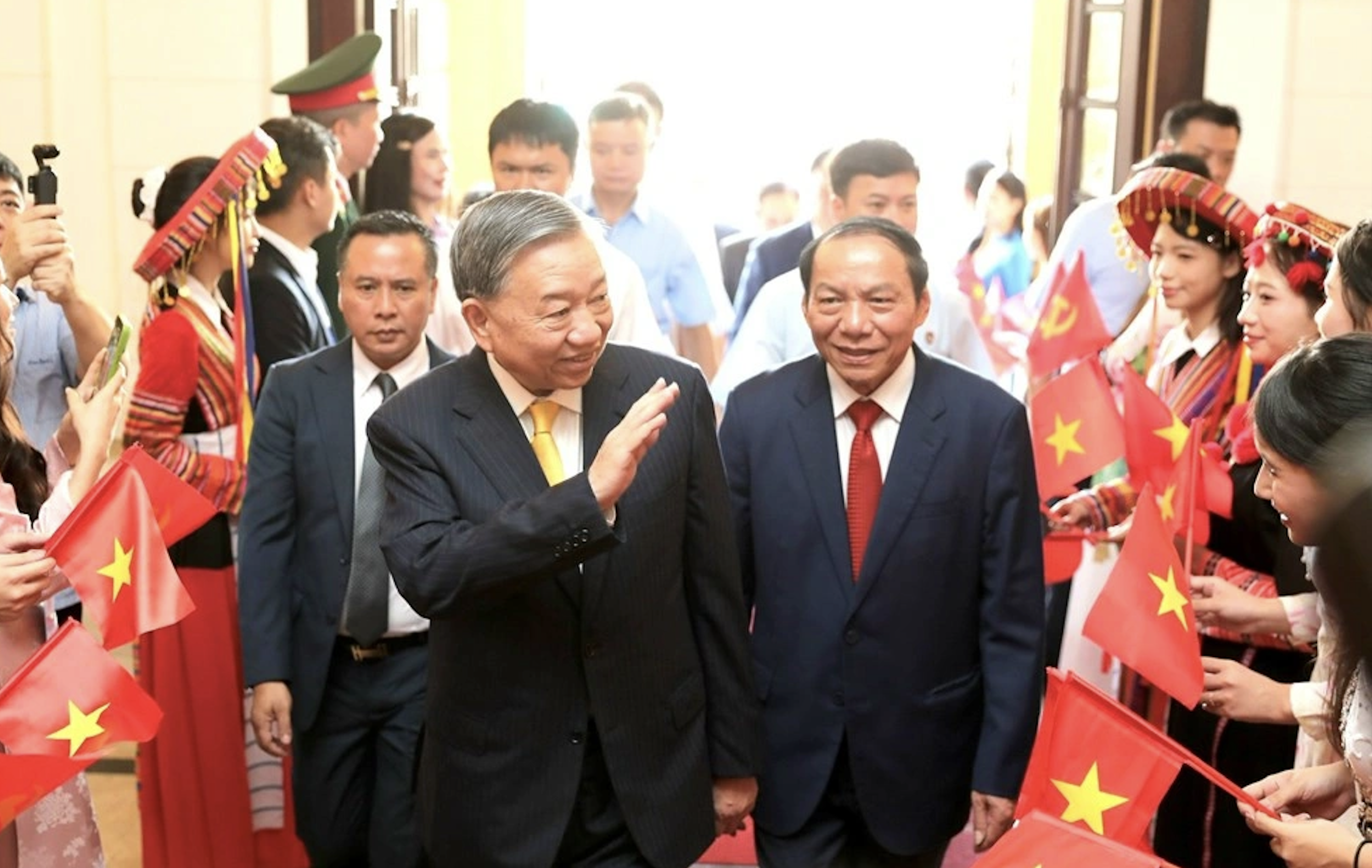

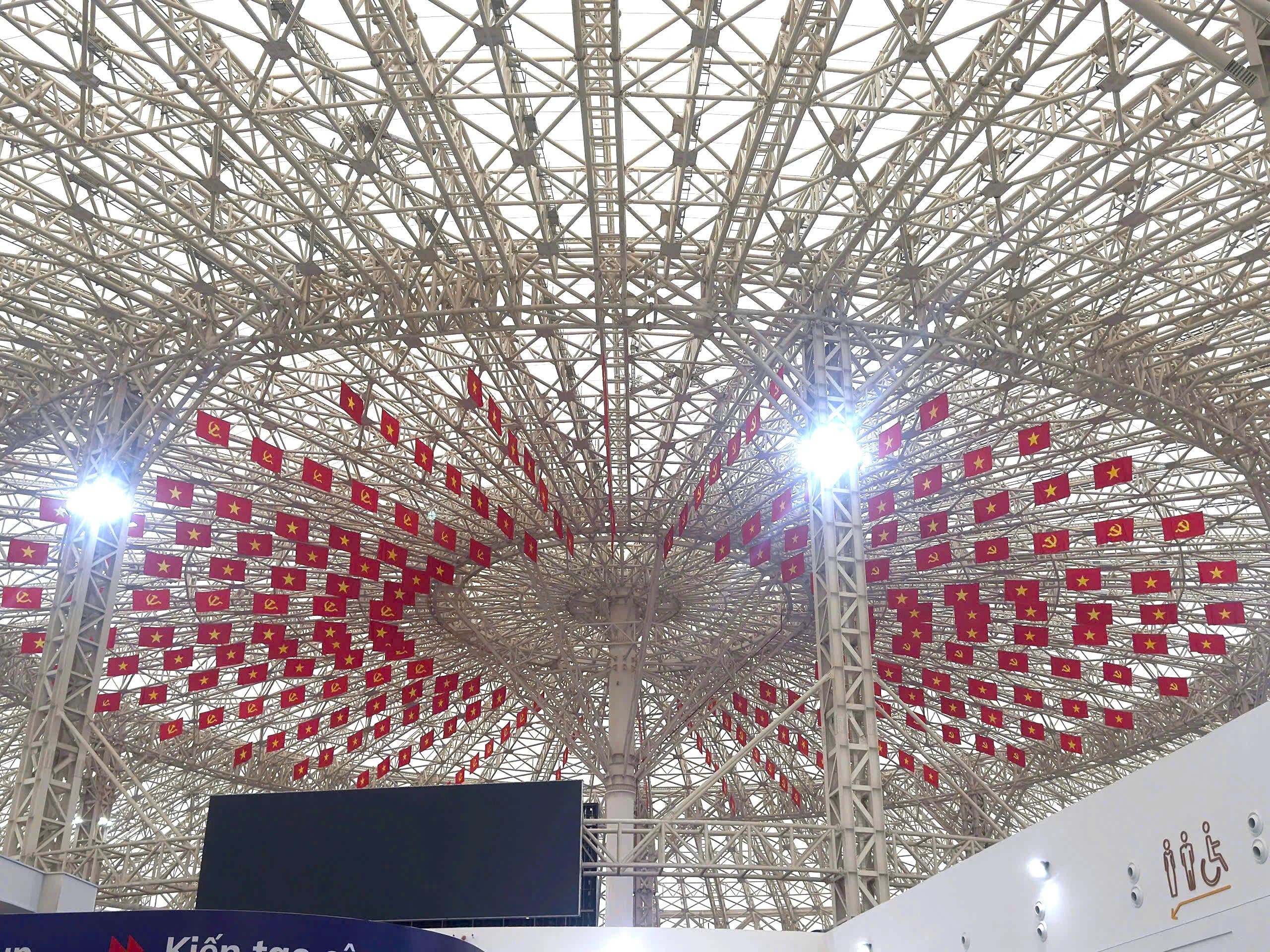

![[Photo] General Secretary To Lam attends the 80th Anniversary of the Cultural Sector's Traditional Day](https://vstatic.vietnam.vn/vietnam/resource/IMAGE/2025/8/23/7a88e6b58502490aa153adf8f0eec2b2)

Comment (0)